Foaming Material

PE FOAM

Ingredient :

- Low Density Polyethylene.

- Foaming agents.

Characters :

- PE (Polyethylene) is a kind of neutral and eco-friendly packing material, especially for metal. It contains no acid or alkaline that night NOT get metal tools rusty. That is to say if the tools packaged in PE material are rusty, that is not caused by the PE FOAM.

- Pure PE is one kind of green neutral eco-friendly material. It is widely applied to packing electronic devices, precision instruments, and medical goods.

- PE FOAM is light and has excellent chemical resistance and solvent resistance, such as toluene, scouring oil, pine fragrance, leaning solvent, machine oil, WD40 etc.

EVA FOAM

Ingredient :

- Low Density Polyethylene.

- Polyethylene vinyl acetate tables EVA (Ethylene-Vinyl Acetate Copolymer).

- Calcium carbonate CaCO3 (talc).

- Bridging, Foaming agent DCP etc.

Characters :

- EVA raw material contains tiny acid that might cause metal rusty if there is no rustproof treatment on the surface of tools.

- EVA is inexpensive, easy to process, and light. It is applied to make commodity and industrial products.

- EVA has excellent chemical resistance and solvents resistance, such as toluene solvent, soiled oil, pine fragrance, washing solvent, machins oil, and WD40 etc.

- The bubble struction of EVA FOAM is independent and even. It is water non-absorbent, excellent recovery, lightweight, and impact-resistant absorbent.

We strongly suggest to use anti-rust oil on the tools’s surface before packing in EVA Foam, because:

- EVA raw material contains tiny acidic that might cause metal tools rusting.

Please pay high attention to this and make sure all tools are conducted rustproof.

If tools packaged in our EVA FOAM are rusty, we are not responsible for it. - Our test shows that the metal tools coated with anti-rust oil can keep from rust well.

Production Process

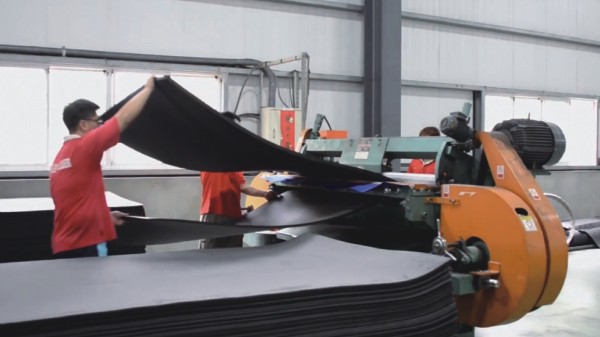

01. Raw material

02. Foaming

03. Foaming board

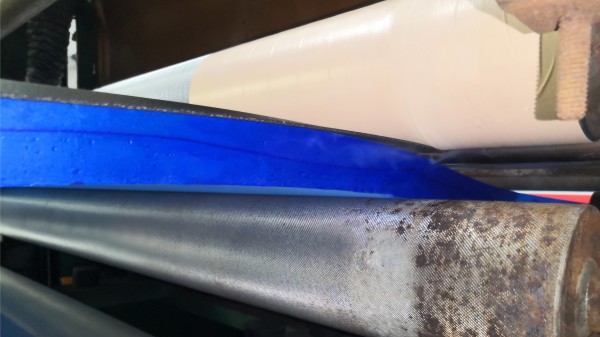

04. Laminating

05. Thermonelectric integrating

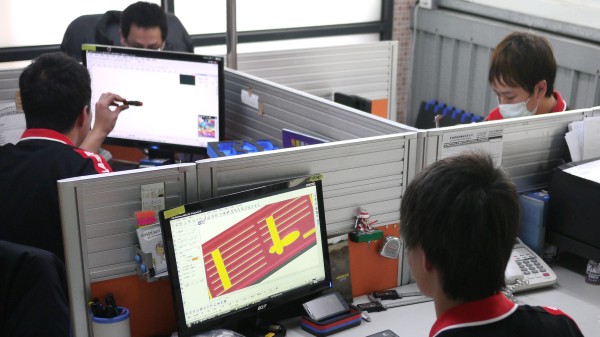

06. Drawing Programming

07. CNC

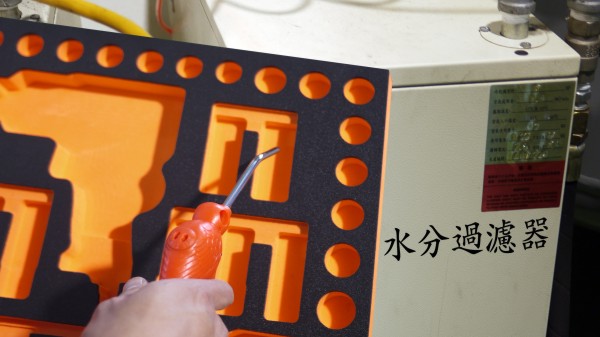

08. Chamfer &Clean

09. Logo/word Laser

10. Logo/word Printing

.jpg)

11. Laying

.jpg)

12. Packaging Shipping

Patent Certificate

Test Standard

- Compliance with the first category of RoHS. (Material or toys indented to be put in the mouth or contact skin longer than 30s.)

With reference to RoHS 2011/65/EU Annex II and its amending Directive (EU) 2015/863 of the European

Parliament and of the Council to determine Cadmium, Lead, Mercury, Cr(VI), PBBs, PBDEs, DBP, BBP, DEHP,

DIBP in our products. - PAHs and other item testing comply with the first category requirement of AfPS.(Material or toys indented to be put in the mouth or contact skin longer than 30s.)

The test results of PAHs (18 items) comply with the limits of PAHs requirement (Category 1) as set by

German Committee on Product Safety (AfPS) GS PAHs. - Passed the inspection of REACH 201 Substances of Very High Concern (SVHC).

According to the ruling of the Curt of Justice of the European Union on the definition of an article under

REACH, and the specified scope as well as analytical technique. Regulation (EC) No 1907/2006 announced

on July 16, 2019, 205 Substances of Very High Concern (SVHC), the test results of the selected

component article are 0.1≦(w/w) in the submitted sample(s).