- Low Density Polyethylene.

- Polyethylene vinyl acetate tables EVA (Ethylene-Vinyl Acetate Copolymer).

- Calcium carbonate CaCO3 (talc).

- Bridging, Foaming agent DCP etc.

- FORMOSA PLASTICS CORPORATION TAISOX® Ethylene Vinyl Acetate Copolymer (EVA) 7350M.

- EVA raw material contains tiny acid that might cause metal rusty if there is no rustproof treatment on the surface of tools.

- EVA is inexpensive, easy to process, and light. It is applied to make commodity and industrial products.

- EVA has excellent chemical resistance and solvents resistance, such as toluene solvent, soiled oil, pine fragrance, washing solvent, machins oil, and WD40 etc.

- The bubble struction of EVA FOAM is independent and even. It is water non-absorbent, excellent recovery, lightweight, and impact-resistant absorbent.

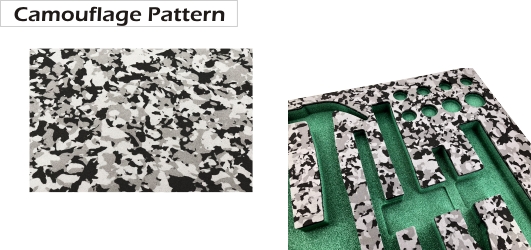

35° Camouflage EVA Foam

Foaming type:chemically cross-linked

Foaming ratio:16±3%

Thickness:40 mm

Sheet Size:W1200 mm x L2300 mm

Hardness:35°±5°

Application:Upper layer

Advantage:Camouflage pattern consists of gray, black, and brown particles. The color blocks vary randomly.

(Few acid in EVA, metal tools need to be rustproofed well)

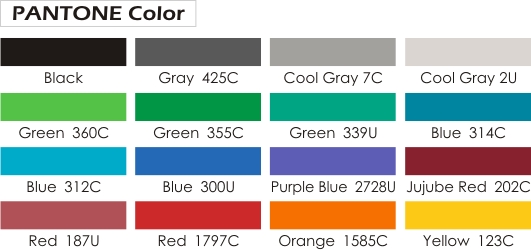

35° EVA Foam

Foaming type:chemically cross-linked

Foaming ratio:16±3%

Thickness:40 mm

Sheet Size: W1200 mm x L2300 mm

Hardness:35°±5°

Application:Upper layer

Advantage:Good Hardness

(Few acid in EVA, metal tools need to be rustproofed well)

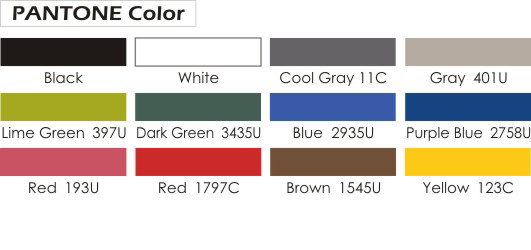

25° EVA Foam

Foaming type:chemically cross-linked

Foaming ratio:23±3%

Thickness:82 mm

Sheet Size:W1200 mm x L2300 mm

Hardness:25°±5°

Application:Bottom layer

Advantage:Various optional colors

(Few acid in EVA, metal tools need to be rustproofed well)